Calcium Acetate Dried: A Comprehensive Product Overview

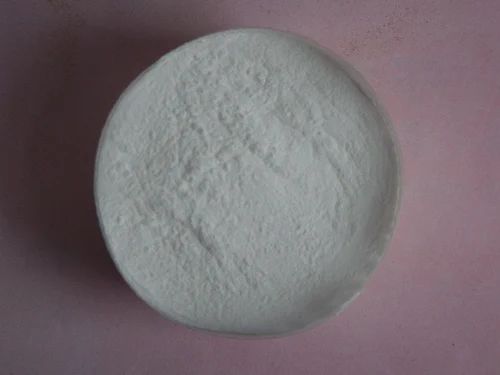

Calcium acetate dried, with the chemical formula C4H6CaO4C_4H_6CaO_4, is a white, odorless powder commonly used in various industries, including pharmaceuticals, food production, and agriculture. Known for its versatility and effectiveness, calcium acetate serves as a vital source of calcium and is utilized in numerous applications, from dietary supplements to food additives. This detailed product description will explore the properties, applications, benefits, and safety measures associated with dried calcium acetate, providing essential insights for those interested in this significant compound.

Chemical Properties

Composition and Structure

Calcium acetate consists of calcium ions (Ca²⁺) and acetate ions (C₂H₃O₂⁻). The dried form is obtained through the removal of water, resulting in a stable, granular powder that can be easily handled and stored. With a molecular weight of approximately 158.17 g/mol, calcium acetate dried is an effective source of calcium in various formulations.

Physical Characteristics

- Appearance: White crystalline powder

- Molecular Weight: 158.17 g/mol

- Solubility: Soluble in water (approximately 1 g per 1 mL)

- Melting Point: Decomposes at high temperatures (around 160 °C or 320 °F)

- pH: Neutral to slightly alkaline in solution

These properties make dried calcium acetate suitable for a wide range of applications across multiple sectors.

Applications of Calcium Acetate Dried

1. Pharmaceuticals

Calcium acetate dried is widely used in the pharmaceutical industry as a calcium supplement. It is particularly beneficial for individuals with calcium deficiencies or those needing additional calcium for bone health. The compound is also used in formulations for renal patients to control hyperphosphatemia, helping to bind dietary phosphate and reduce its absorption.

2. Food Industry

In the food industry, calcium acetate dried serves as a food additive and preservative. It is used in various products, including processed cheeses and baked goods, to enhance texture and stability. Additionally, it acts as a firming agent in pickled vegetables, ensuring quality and longevity.

3. Agriculture

Calcium acetate dried is employed as a calcium source in fertilizers for agricultural applications. It helps improve soil quality and promotes healthy plant growth. The compound can be added to soil to correct calcium deficiencies, which is essential for various crops, including fruits and vegetables.

4. Chemical Production

In chemical manufacturing, dried calcium acetate is utilized as a precursor in the synthesis of other calcium compounds. Its versatility makes it an essential component in producing various industrial chemicals and materials, including polymers and coatings.

5. Laboratory Reagent

Calcium acetate dried is commonly used as a reagent in laboratory settings. It serves various purposes, such as a buffer component in analytical chemistry and a source of calcium ions in biochemical assays. Researchers rely on its stability and solubility for accurate experimental results.

Advantages of Using Calcium Acetate Dried

1. High Calcium Content

One of the key benefits of calcium acetate dried is its high calcium content. As a reliable source of calcium, it effectively supports bone health, making it a popular choice in dietary supplements and pharmaceuticals.

2. Versatility

The diverse applications of calcium acetate dried highlight its versatility. From pharmaceuticals and food production to agriculture and chemical manufacturing, its effectiveness across multiple sectors showcases its adaptability and importance in various industries.

3. Cost-Effectiveness

Compared to other calcium sources, dried calcium acetate is relatively inexpensive. This cost-effectiveness makes it an attractive option for manufacturers and researchers seeking reliable solutions without significant financial burdens.

4. Stability

Calcium acetate dried is stable under normal storage conditions, ensuring its reliability in various applications. Proper handling and storage practices will maintain its integrity over time.

How to Use Calcium Acetate Dried

1. In Pharmaceuticals

When using calcium acetate dried as a supplement:

- Dosage: Follow manufacturer guidelines for appropriate dosage based on individual calcium needs. Typical dosages may vary, so consult a healthcare professional for personalized recommendations.

- Formulation: Incorporate calcium acetate into formulations for tablets or capsules, ensuring accurate dosing for effective results.

2. In Food Production

For food applications:

- Incorporation: Use calcium acetate dried according to established guidelines for food safety and regulatory compliance. It can be added to processed foods to enhance texture and stability.

- Measurement: Ensure accurate dosing to achieve the desired effects in food products, particularly in cheese-making and baking.

3. In Agriculture

In agricultural applications:

- Application: Mix calcium acetate dried into fertilizers according to soil tests and crop requirements. Typical application rates may vary, but it is essential to assess soil nutrient levels for optimal effectiveness.

- Monitoring: Regularly assess soil health and plant growth to adjust application rates as needed.

4. In Chemical Production

For chemical manufacturing:

- Preparation: Utilize calcium acetate dried as a precursor for synthesizing various calcium compounds.

- Testing: Conduct regular quality checks to maintain product standards throughout the production process.

5. In Laboratory Use

In laboratory applications:

- Preparation: Dissolve calcium acetate dried in distilled water to prepare buffer solutions for analytical assays.

- Protocol Adherence: Follow established laboratory methods for accurate and reliable results, particularly in biochemical analyses.

Safety and Handling

1. Toxicity

Calcium acetate dried is generally considered safe when handled properly. It is non-toxic and poses minimal health risks. However, it can cause mild irritation to the skin, eyes, and respiratory system if inhaled or ingested in large quantities.

2. Protective Measures

When working with calcium acetate dried, it is crucial to:

- Wear Protective Gear: Use gloves, goggles, and appropriate protective clothing to minimize exposure risks.

- Ensure Ventilation: Work in a well-ventilated area to avoid inhaling dust.

3. Storage

Store calcium acetate dried in a cool, dry place away from incompatible substances. Ensure that containers are tightly sealed to prevent moisture absorption, which can lead to degradation.

Environmental Considerations

When using calcium acetate dried, it is essential to consider its environmental impact. Proper disposal methods should be followed to minimize harm to the environment, particularly due to nutrient runoff that can lead to eutrophication in water bodies. Always adhere to local regulations regarding chemical waste disposal.

Conclusion

Calcium acetate dried is a versatile and essential compound utilized across various industries, including pharmaceuticals, food production, agriculture, and chemical manufacturing. Its unique properties, such as high calcium content and stability, make it an invaluable resource for professionals and manufacturers alike.

When purchasing calcium acetate dried, choose reputable suppliers that provide high-quality products and detailed safety data sheets. Understanding its applications, benefits, and safety measures will help you maximize the potential of this remarkable compound in your projects.

Whether you’re a health professional seeking effective calcium supplements, a food manufacturer looking to enhance product quality, or an agricultural expert aiming to improve crop yields, calcium acetate dried can meet your needs. Embrace the advantages of this compound and unlock new possibilities in your field!

Reviews

There are no reviews yet.